CVT Warmer/Cooler Flushing

The CVT oil warmer/cooler has two closed loops to exchange heat between the CVT and the engine. After starting the vehicle, the engine helps warm the CVT fluid to operating temperature. During extended operation, the exchange provides a cooling effect as heat from the CVT is exchanged into the engine coolant.

To prevent the CVT from overheating, inspect the engine coolant and replace the engine coolant if it is degraded. Per the Nissan service manual engine coolant must be replaced at 105,000 miles or 84 months, whichever comes earlier. Make sure the engine coolant lines are not obstructed and coolant can freely flow into the CVT warmer/cooler. It is also important to inspect the engine air filter and replace it if dirty or obstructed. Excess engine temperature will overheat the CVT fluid and may cause premature failure.

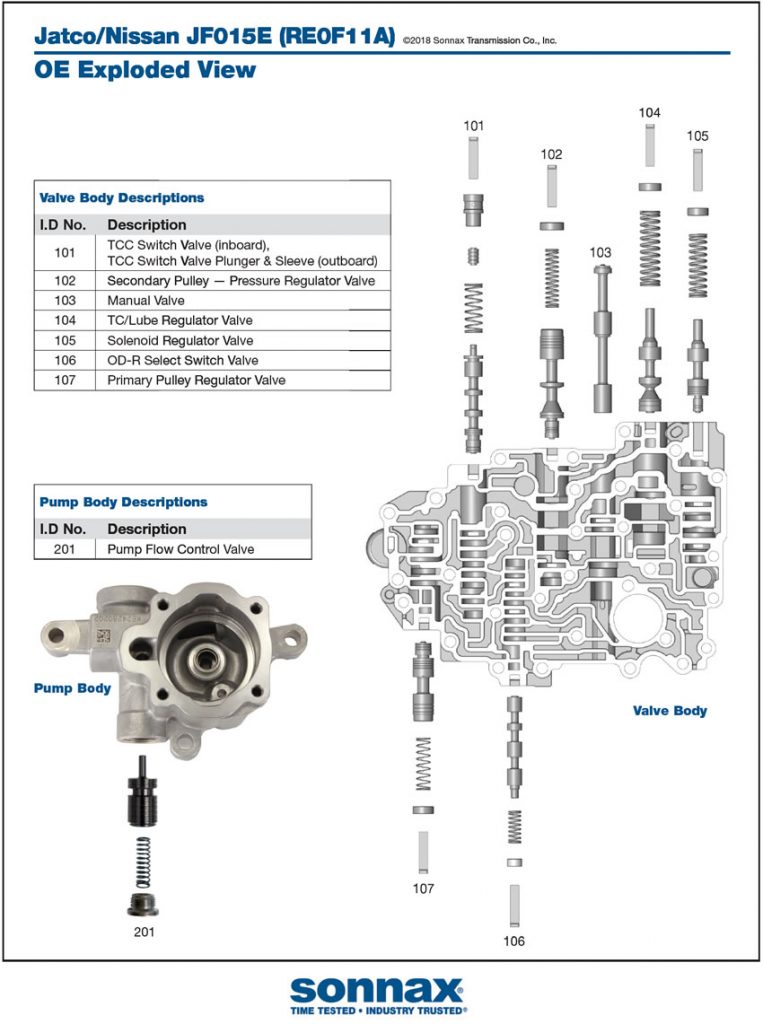

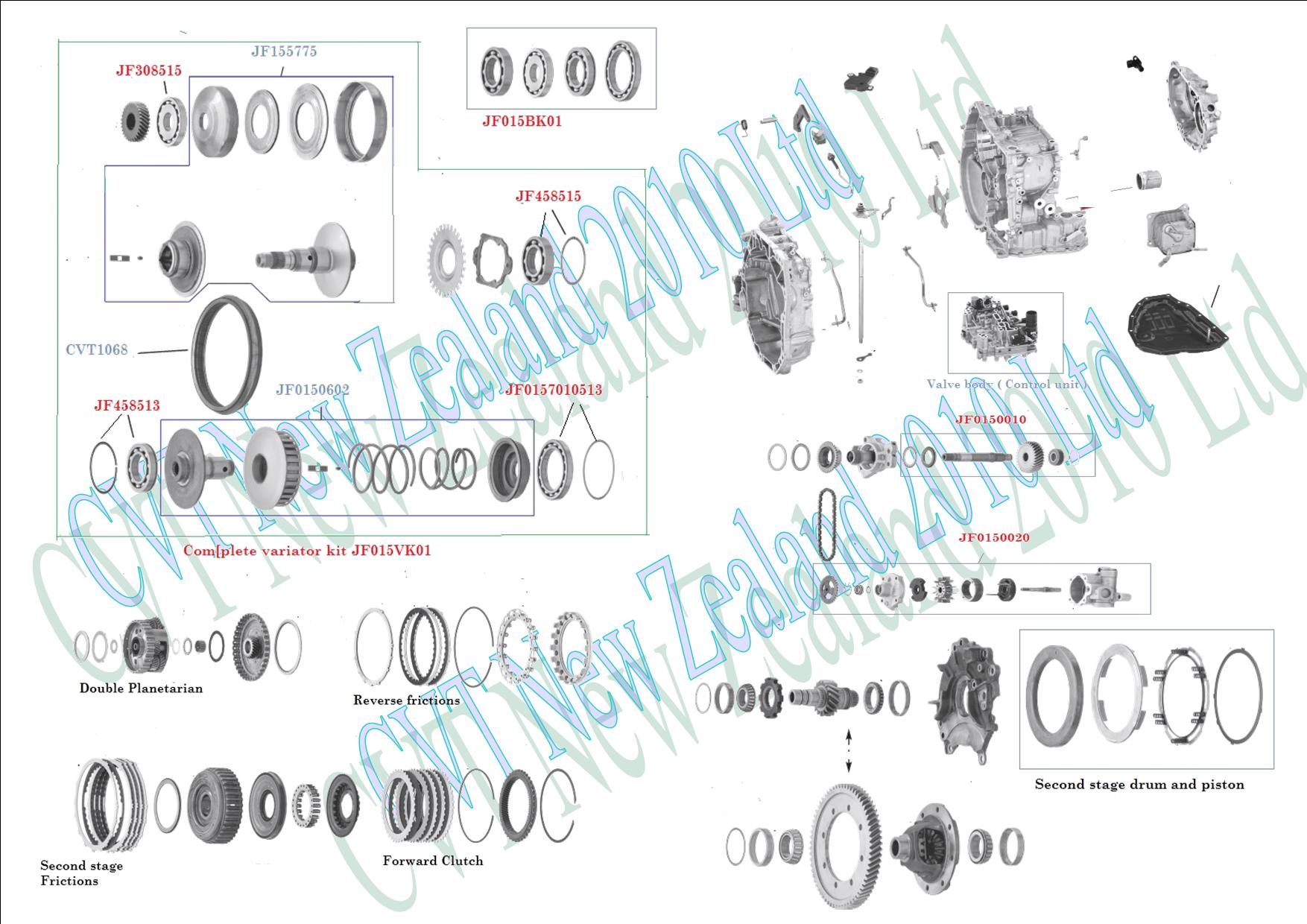

Transmission repair manuals CVT JF011E (RE0F10A), RE0F06A, diagrams, guides, tips and free download PDF instructions. Fluid capacity and type, valve body and solenoids charts. Jf015e converter nissan juke 07c 07d codes 1 jf015e.tc01 jf015e converter nissan micra 07a/07e code 1 jf015e.tc02 jf015e torque converter nissan note 1200cc 07n 1 jf015e.tc03 nissan micra 2014 '07k' 1 jf015e.tc04 transmission tools n (000280) ref description quantity part no jf015e transmission dis/assemble toolkit 1 jf015e.tool01 valve body n.

The CVT fluid should also be inspected every 30,000 miles and replaced if burnt, contaminated, or otherwise degraded. Replace CVT fluid with NS-3 rated fluid only for all vehicles except the 2012 Versa, which used NS-2.

CVT Fluid Type and Fill Level

NOTE: The fluid change interval for the JF015E CVT is every 60,000 miles. If the vehicle has been driven over 60,000 miles on a Berkeley Standard CVT, maintenance records showing proof of fluid change(s) at 60,000 mile or earlier intervals must be provided in order to ensure warranty coverage.

ATSG is a technical support service specifically for the Automatic Transmission Industry. We offer a Technical Hotline, Books, Software, Bulletins, Wiring Diagrams, Seminars, and Technical Courses to the Automatic Transmission Professional. In this video, i go through my first the Cvt7 (JF015E) showing the clutch packs, planetary gearset, valvebody and pulleys. We get alot of calls on these so t. Jatco Transmission Manual Transmission repair manuals JF015E (RE0F11A) CVT7. Information about rebuild transmission CVT JF015E (RE0F11A) In 2010, the Japanese company Jatco released a new generation of JF015E variators, which were intended for use on small cars.

NOTE: For Nissan Sentra and Versa model years 2013 and newer, Nissan NS-3 rated fluid should be used. For the 2012 Versa, NS-2 rated fluid should be used. Nissan NS-3 is NOT interchangable with NS-2. The use of the incorrect fluid will lead to premature wear and overheating of the CVT and will invalidate the warranty coverage.

After the CVT has been installed in the vehicle, the CVT should be filled with fluid from the drain plug at the bottom of the oil pan. There is an overflow tube in the oil pan that indicates the correct fluid level for this transmission. The volume of the CVT fluid is dependent on temperature, and when filling or adjusting CVT fluid level, the fluid temperature should be 35C – 45C (95 to 113°F).

CVT Fluid Fill Instructions

1. Engage the parking brake and lift up the vehicle.

2. Check that there is no CVT fluid leakage.

3. Remove the drain plug.

4. Install the charging pipe set (KV311039S0) (A) into the drain plug hole.

5. Tighten the charging pipe by hand.

6. Install the ATF changer hose to the charging pipe. Press the ATF changer hose all the way onto the charging pipe until it stops.

7. Fill approximately 3 liters (3.2 US qt) of NS-3 CVT fluid (NS-2 for 2012 Versa)

8. Lift down the vehicle.

9. Start the engine.

10. While depressing the brake pedal, shift the selector lever to the entire position from “P” to “L”, and shift it to the “P” position. Hold the lever at each position for 5 seconds.

11. Check the scan tool to ensure the fluid temperature is 35°C (95°F) to 45°C (113°F).

12. Lift up the vehicle.

13. Remove the drain plug and confirm that the CVT fluid is drained from the overflow tube. Perform this work with the vehicle idling.

14. If the CVT fluid does not drain reinstall the changing pipe and ½ liter of CVT fluid and repeat steps 8 – 12.

15. When the flow of CVT fluid slows to a drip, tighten the drain plug to the specified torque.

16. Lift down the vehicle.

17. Using a scan tool, reset CVT Fluid Deterioration in the TCM

18. Stop the engine.

Alternative Fill Procedure

1. Engage the parking brake and lift up the vehicle.

2. Check that there is no CVT fluid leakage.

3. Remove the drain plug and place a pan or container under the oil pan to catch excess fluid.

4. Remove the fill plug (see image below) near the CVT pass-through connector. The fill plug is near the bottom of the transmission and faces upwards.

5. Attach a hose or funnel to the open fill hole near the CVT pass-through connector.

6. Fill the transmission with NS-3 (NS-2 for 2012 Versa) CVT fluid until fluid comes out of the drain plug. The CVT will take approximately 3-4 liters (3.2-4.3 US qt) of NS-3 CVT (NS-2 for 2012 Versa) fluid before the fluid begins to drain.

7. Remove the hose or funnel and reinsert the fill plug. Lift down the vehicle.

8. Start the engine.

9. While depressing the brake pedal, shift the selector lever to the entire position from “P” to “L”, and shift it to the “P” position. Hold the lever at each position for 5 seconds.

10. Check the scan tool to ensure the fluid temperature is 35°C (95°F) to 45°C (113°F).

11. Lift up the vehicle.

12. Confirm that the CVT fluid is drained from the overflow tube. Perform this work with the vehicle idling.

13. If the CVT fluid does not drain repeat steps 3 – 12. Add ½ liter of CVT fluid in step 6.

14. When the flow of CVT fluid slows to a drip, tighten the drain plug to the specified torque.

15. Lift down the vehicle.

16. Using a scan tool, reset CVT Fluid Deterioration in the TCM

17. Stop the engine.

Fill Plug and Fill Hole

TCM Reprogramming

The vehicle does not require programming unless the TCM software is affected by a service bulletin. To check the TCM software see instructions below:

First, find TCM Part Number with Scan Tool. The TCM hardware is a computer chip with identical hardware and the part number represents the software the TCM is programmed with. The TCM part number will start with 31036-XXXX.

Jf015e Cvt Manual

If the TCM part number is any of the ones on the table below, the TCM needs to be reprogrammed with updated software. This can be done either with a Consult 3 scanner and programmer (available at Nissan dealerships), or with the RAP Kit but Drew Technologies.

NOTE: The JF015E transmission or valve body does not come with a programming CD.

NOTE: If there are any diagnostic trouble codes (DTC) the transmission may not program. Clear all DTCs before proceeding with programming. If there are persistent DTCs, these must be addressed and cleared before programming can proceed.

Jf015e Manual Pdf

Test Drive and TCM Calibration

After the transmission has been installed use a scan tool to verify the vehicle does not have any diagnostic trouble codes. If the vehicle does not have any codes, proceed with the clutch point relearn (below), and test drive the vehicle for an additional 15 – 20 minutes to allow the TCM to self-calibrate. Do not drive the vehicle if it has any DTCs the cannot be cleared before the test drive.

The test drive should cover a range of speeds in both forward and reverse. The vehicle may shift abnormally at the beginning of the test drive but should normalize in 20 minutes or less. If the MIL / check engine light illuminates during the test drive, do not continue driving.

Re-scan the vehicle after the test drive to ensure there are no DTCs.

Clutch Point Relearn

The JF015E is a CVT combined with a two-speed transmission (auxiliary gearbox). When the valve body or transmission is replaced, the TCM must re-learn the shift point on the two speed transmission. The auxiliary gearbox is programmed to shift at 20 mph – 45 mph depending on engine RPM and load.

CAUTION: If clutch touch point learning is not performed, the auxiliary transmission may not shift or may shift at the wrong speed. You may feel shift shock when the auxiliary transmission shifts, especially between 20-45 mph and a downshift shock when decelerating below 10 mph.

NOTE: This manual procedure is only needed if the auto procedure is not available in C-III

Plus. If using an aftermarket scan tool, you must first erase TCM memory and TCM self learning data.

Jf015e Transmission Repair Manual Pdf

a. Start the engine and warm up the CVT fluid to 50°C (122°F).

NOTE: Confirm the CVT fluid temperature by “FLUID TEMP” in “Data Monitor”.

b. Turn the air conditioner OFF.

c. Move the shift selector to P, turn the ignition OFF, and then wait 5 seconds.

d. Start the engine and allow it to idle for 5 seconds.

e. Turn the ignition OFF and then wait 30 seconds.

f. Perform Step “e” to Step “f” two more times (Total: Three times).

g. Start the engine.

h. Allow engine to idle for 30 seconds.

i. Move the shift selector to D.

j. Accelerate the vehicle from 0 km/h (0 MPH) to 65 km/h (40 MPH) at low throttle

(0.5/8 – 1/8).

k. Decelerate the vehicle to 30 km/h (18 MPH) or less without using brakes.

l. Stop the vehicle and move the shift selector to P.

m. Turn the ignition OFF and wait 5 seconds or more.

n. Restart the engine.

o. Perform Step “j” to Step “o” four times (Total: Five times).

p. Move the shift selector to D.

q. Accelerate the vehicle from 0 km/h (0 MPH) to 45 km/h (28 MPH) at low throttle

(0.5/8 – 1/8).

r. Stop the vehicle and move the shift selector to P.

s. Turn the ignition OFF for 5 seconds or more and then restart the engine.

t. Perform Steps “q” to Step “t” four times (Total: Five times).

u. Drive the vehicle and check that no shock occurs while shifting gears.

Jf015e Manual Pdf

Source material: Nissan CVT manuals and TSBs